Introduction: Why the Fuel Pump Is a Critical Engine Component

The fuel pump is often overlooked, yet it plays a vital role in the proper functioning of your vehicle’s engine. Acting as the heart of the fuel delivery system, the fuel pump ensures a steady flow of fuel from the tank to the engine’s combustion chambers. Without a working fuel pump, your vehicle cannot run efficiently—or at all. As cars become more sophisticated, understanding the importance of fuel pumps can help you diagnose issues early and maintain optimal engine performance.

Understanding the Function of a Fuel Pump

A fuel pump’s primary role is to transfer fuel from the tank to the engine at the correct pressure required for combustion. This process involves drawing fuel through the fuel lines and delivering it to the fuel injectors or carburetor, depending on the vehicle. Modern fuel pumps are electronically controlled and are designed to operate under high pressure to ensure consistent fuel flow. A malfunctioning pump can cause a host of problems, including stalling, poor acceleration, or complete engine failure.

Types of Fuel Pumps and Their Applications

There are mainly two types of fuel pumps used in vehicles: mechanical and electric. Mechanical fuel pumps are typically found in older vehicles with carbureted engines and operate via a mechanical linkage connected to the engine. Electric fuel pumps, which are more common today, are installed inside the fuel tank and use an electric motor to generate the necessary pressure. Within electric pumps, there are variations such as in-tank pumps and in-line pumps, each suited for different engine requirements and vehicle designs.

Signs Your Fuel Pump Might Be Failing

Recognizing the early signs of a failing fuel pump can save you from unexpected breakdowns. Common symptoms include difficulty starting the vehicle, engine sputtering, loss of power during acceleration, or a whining noise coming from the fuel tank area. You might also notice the engine stalling intermittently or experiencing reduced fuel efficiency. If you experience any of these issues, it’s crucial to have your fuel pump inspected promptly to prevent further engine damage.

Maintenance and Replacement of Fuel Pumps

Fuel pumps are generally durable but are not immune to wear and tear. Regular maintenance includes replacing the fuel filter, which prevents debris from reaching the pump and causing damage. If turbocharger fails, replacement is often necessary. Installing a new pump requires careful selection of the correct part compatible with your vehicle’s make and model. Professional installation is recommended to ensure proper functioning and to avoid fuel leaks or electrical issues.

The Future of Fuel Pump Technology

Advances in automotive technology continue to improve fuel pump efficiency and durability. Innovations such as variable-pressure fuel pumps and intelligent control systems help optimize fuel delivery based on real-time engine demands. As electric and hybrid vehicles become more prevalent, fuel pump designs are also evolving to integrate seamlessly with alternative fuel systems. Researchers are exploring quieter, more reliable pumps that can operate under extreme conditions, ensuring better performance and longevity.

Conclusion: The Vital Role of a Well-Maintained Fuel Pump

In conclusion, the fuel pump is an indispensable component that ensures your engine receives a consistent supply of fuel for optimal performance. Regular maintenance, prompt repairs, and understanding the signs of failure can help you avoid costly breakdowns and extend the lifespan of your vehicle. As automotive technology advances, staying informed about your fuel system components will keep your vehicle running smoothly and efficiently for years to come.

Take hold of the Beauty associated with Down Under Typically the Allure of Aussie Art Prints

Australian art prints are more than simply decorative pieces; these people are a party of the country’s breathtaking landscapes, lively wildlife, and rich cultural tapestry. These types of prints serve as a window into the diverse elegance and artistic heritage of Australia, enabling you to bring a bit of the area down under into the home or work area. Whether you’re a great art enthusiast or perhaps someone looking to add an special touch in your decor, Australian art prints offer you a compelling and meaningful option.

Australian wall art of Australian art styles is their emphasis on the country’s iconic landscapes. In the stunning red sands of Uluru for the lush greenery in the Daintree Rainforest, these images capture the inclusion of of Australia’s environment. Large, vivid designs of these moments can evoke emotions of chance, tranquility, or even wonder, and function as an everyday reminder of the country’s extraordinary geography.

Creatures imagery is in addition a popular style in Australian skill prints. Australia hosts some of the world’s most unusual pets, including kangaroos, koalas, and colorful parrots. Artistic representations involving these creatures—whether genuine or stylized—add a new lively, playful aspect to your decoration. Additionally they foster the greater appreciation intended for Australia’s rich biodiversity, making them ideal for nature lovers and animal enthusiasts likewise.

Cultural heritage performs a vital function in Australian art, especially Indigenous art. Aboriginal dot works of art, Dreamtime stories, and even symbolic motifs are usually frequently featured within art prints, providing a glimpse into Australia’s ancient practices and spiritual thinking. Displaying these widely significant artworks certainly not only enhances your own space aesthetically nevertheless also shows admiration for the land’s original custodians and their stories.

Contemporary Australian artists add a modern angle to the art print scene together with abstract designs, streets art influences, and bold color palettes. These modern styles reflect Australia’s active urban culture and artistic innovation. Incorporating such pieces directly into your decor can create a vibrant, energetic atmosphere that celebrates Australia’s evolving artistic identification.

Personalization options are usually accessible when buying Australian art styles. Many galleries and online stores present customizable framing, dimensions options, and even associated with creating unique pieces. Personalizing your print ensures that complements your inside design and becomes an unique appearance of your connection to Australia.

Within conclusion, Australian art prints are a versatile plus meaningful way to be able to decorate your room. They encapsulate typically the pure beauty, wildlife, and cultural richness associated with Australia, making these people perfect for including both aesthetic charm and cultural level. Whether you like scenic landscapes, wild animals, Indigenous art, or contemporary designs, these kinds of prints allow a person to carry some Australia’s spirit together with you wherever you get.

Using the Spirit of Down under Home The Attraction of Australian Fine art Prints

Australian art designs are a captivating approach to celebrate the particular country’s diverse landscapes, rich cultural historical past, and vibrant artsy scene. These images serve as lovely, affordable art bits that can immediately transform any place, from living rooms to offices, directly into a reflection of Australia’s unique attraction. Whether you’re the proud Aussie or perhaps an admirer regarding Down Under’s organic wonders and artistic traditions, Australian wall arts offer a meaningful solution to bring a new piece of Quotes into your everyday life.

Probably the most impressive features of Foreign art prints will be their focus about the country’s well-known natural scenery. Through the majestic Uluru and the sweeping beaches of Bondi to the lush rainforests of Queensland and even the rugged Einzugsgebiet, these images capture the breathtaking beauty of Australia’s diverse environments. Art designs of the landscapes permit you to delight in their serenity in addition to grandeur from anyplace, creating a relaxing or inspiring ambiance in your house or work area.

As well as Australian framed prints , Foreign art prints often showcase the country’s amazing wildlife. Kangaroos, koalas, kookaburras, and platypuses are usually featured in vibrant, detailed pictures or photographs. These images not simply add a playful and lively feel to your decoration and also serve while a tribute to be able to Australia’s unique gyvūnai, fostering a further appreciation for the natural biodiversity.

Cultural expression are also notable in Australian wall arts. Indigenous art, with its characteristic dot habits, symbolic motifs, and storytelling elements, performs a vital position in showcasing Australia’s rich Aboriginal traditions. Authentic Indigenous prints can serve while powerful conversation beginners and cultural connectors, honoring the heavy spiritual traditions involving the land’s 1st Nations people. Choosing such prints gives depth, meaning, and even a sense of connection to typically the land’s history.

Modern Australian artists contribute a fresh perspective in order to the produce landscape with their innovative styles and contemporary themes. Abstract combinaison, street art impact on, and vibrant pallettes reflect Australia’s powerful urban culture and artistic evolution. These kinds of modern prints can easily energize your place and demonstrate typically the country’s creative vibrancy, making them best for stylish, modern-day interiors.

Personalization is usually also an essential aspect of Australian art prints. Many on the web platforms offer choices options, allowing you to pick sizes, framing models, or even create personalized compositions. This particular flexibility ensures that will your selected print matches your existing interior decoration and becomes an unique expression of your connection to be able to Australia.

In conclusion, Australian wall arts are the excellent investment in both aesthetic elegance and cultural importance. They provide a versatile approach to beautify your space using images that suggest adventure, beauty, plus heritage. Whether an individual prefer natural scenery, wildlife, Indigenous motifs, or modern fine art, these prints let you celebrate the property Down Under plus keep its nature alive inside your daily environment.

Fuel Pump Fundamentals: The Lifeline of Your Vehicle’s Engine

Introduction: The Heartbeat of the Fuel System

A vehicle’s fuel pump is a crucial component that often goes unnoticed until it malfunctions. Serving as the engine’s lifeline, the fuel pump supplies a steady stream of fuel from the tank to the engine’s combustion chambers. Without it, the vehicle cannot run efficiently or may not start at all. Understanding how a fuel pump works and its importance in vehicle operation can help drivers better maintain their cars and recognize early signs of trouble.

How a Fuel Pump Works: Delivering Power to the Engine

The primary function of a fuel pump is to draw fuel from the tank and push it through fuel lines to the engine at the required pressure. This process ensures that fuel injectors or carburetors receive the precise amount of fuel needed for combustion. Modern fuel pumps are usually electric and integrated into the fuel tank, providing a reliable and consistent supply. Proper fuel pressure maintained by the pump is essential for optimal engine performance and fuel efficiency.

Types of Fuel Pumps and Their Specific Uses

There are mainly two types of fuel pumps: mechanical and electric. Mechanical fuel pumps are typically found in older vehicles with carbureted engines, operating via mechanical linkages connected to the engine. Bosch fuel injector , which dominate today’s automotive landscape, are installed inside the fuel tank and powered by electricity. In-tank pumps are the most common, designed for quiet operation and protection from debris, while in-line pumps are mounted outside the tank for specialized applications.

Common Symptoms of a Failing Fuel Pump

Knowing the signs of a failing fuel pump can save you from unexpected breakdowns. Symptoms include difficulty starting the vehicle, engine sputtering or stalling, loss of power during acceleration, and a whining noise coming from the fuel tank area. You might also notice reduced fuel efficiency or your vehicle refusing to start altogether. Addressing these signs early can help prevent further damage to the engine and related components.

Maintaining and Replacing Your Fuel Pump

While fuel pumps are built to last, they can wear out over time due to debris, corrosion, or electrical issues. Regularly replacing the fuel filter can extend the life of your pump by preventing contaminants from clogging it. If the pump fails, replacement is necessary. Ensuring you choose the right pump for your vehicle and having it installed by professionals can prevent potential leaks or electrical problems that can arise from improper installation.

The Future of Fuel Pump Technology

Innovations in automotive technology are leading to more efficient and durable fuel pump systems. Variable-pressure pumps and smart control modules are being developed to optimize fuel delivery based on real-time engine demands. As electric and hybrid vehicles become more common, fuel pump designs are evolving to accommodate alternative fuels and integrated energy management systems. These advancements aim to improve fuel efficiency, reduce noise, and extend service life.

Conclusion: Keep Your Fuel System in Top Shape

In summary, the fuel pump is an essential component that ensures your vehicle runs smoothly and efficiently. Regular maintenance, prompt attention to warning signs, and understanding its function can help you avoid costly repairs and breakdowns. As technology continues to advance, staying informed about your vehicle’s fuel system will ensure you enjoy reliable performance and prolonged engine life for years to come.

The Jackpot Quest Investigating the Finest Digital Slot Games Currently Available

As this digital age keeps to transform our world of gaming, online slot games have claimed the focal stage, captivating players worldwide with their vibrant graphics, immersive themes, and that thrill of potential wins. Ranging from classic fruit machines to intricate multi-reel adventures, the variety available today is staggering, guaranteeing that there is a selection for everyone, no matter preference or experience level.

For both seasoned players as well as newcomers, the quest for the best online slot games can feel like a thrilling journey of its own. With so many options at your fingertips, it is crucial to navigate through the offerings to discover which games provide not just excitement, but also innovative features and rewarding payouts. In this investigation, we shall explore into the top contenders that promise to offer memorable experiences and possibly a jackpot moment that could change your life.

Top Virtual Slot Titles of 2023

In this year, the world of virtual slot titles has continued to engage gamers with fresh themes, stunning visuals, and entertaining play. One remarkable game this year is "Mega Moolah", known for its unprecedented growing prizes. Players are attracted to its adventure concept and the chance to win transformative sums of cash from its famous jackpot feature. The mobile-optimized layout guarantees that fans can enjoy the thrill of spinning the slots anytime and anywhere.

Another favored choice among enthusiasts is "Starburst," a classic that has preserved its charm over the years. With its lively gems and growing wild symbols, Starburst offers an engaging play that keeps gamers returning back for additional excitement. 다낭 마사지 of play and high RTP make it an ideal option for both beginners and seasoned players alike. The game’s stunning visuals and lucrative features contribute to its standing as one of the top internet slot games available.

Finally, "Gonzo’s Quest" has drawn the attention of many in this year with its unique avalanche feature, which rewards consecutive wins with rising multipliers. Gamers accompany the intrepid Gonzo on a journey for riches, immersing themselves in a gripping narrative. The combination of engaging visuals, thrilling mechanics, and potential for large wins has solidified its status as a favorite among virtual slot game lovers this year.

Tips for Enhancing Your Profits

To maximize your profits in online slot games, it is essential to comprehend the significance of choosing the right game. Choose slots with higher RTP percentages, as these games typically provide superior odds for winning in the long term. Investigate various titles and concentrate on those that provide lavish payouts and features. Additionally, search for games with progressive jackpots, as these can bring life-changing sums if you strike it lucky.

Effectively managing your bankroll effectively is vital when playing online slots. Establish a budget before you start and stick to it, irrespective of your wins or defeats. This discipline helps prevent rash decisions that can lead to overspending. Consider playing at reduced stakes to increase the length of your gaming session, which gives you more chances to land winning combinations without quickly exhausting your resources.

Finally, take full advantage of bonuses and promotions that online casinos provide. Many platforms offer free spins, welcome bonuses, and loyalty rewards that can improve your gameplay experience. Make use of these deals to lengthen your game time and boost your chances of scoring a big win. Always read the terms and conditions associated with bonuses to ensure you comprehend the playthrough conditions before redeeming them.

The Prospects of Digital Slots

The outlook of digital slot games promises an dynamic blend of creativity and creativity, driven by advancements in technology. We can anticipate increasingly immersive experiences through VR and AR, letting players to experience a completely interactive gaming world. This transition not only enhances player engagement but also introduces new narrative elements to the games, making each spin feel like part of a larger narrative.

In addition to technological enhancements, the incorporation of AI will be crucial in personalizing the gaming experience. With artificial intelligence, online games can tailor themselves to personal player preferences, offering personalized bonuses, themes, and gameplay features that appeal with players. This customized approach will likely foster a deeper connection between users and their beloved games, keeping them invested for longer amounts of time.

Additionally, as the digital gaming sector continues to face criticism regarding equity and safe gambling practices, future digital games will likely prioritize clarity and gamer protection. New laws may lead to enhanced security measures and fairness guarantees, ensuring that users feel secure and assured when playing the reels. This shift towards accountability will be vital to creating a sustainable and trustworthy online slot environment.

Discover the Top Places for the Best Massage in Da Nang: Your Guide to Ultimate Relaxation

Da Nang, with its stunning beaches, vibrant culture, and delicious cuisine, is a must-visit destination in Vietnam. But beyond sightseeing, many travelers seek ways to unwind and rejuvenate during their stay. Massage therapy is a popular choice, offering relief from travel fatigue and a chance to experience authentic Vietnamese healing traditions. With so many options available, finding the best massage in Da Nang can seem overwhelming — but this guide will help you navigate the top spots for unrivaled relaxation.

One of the most reputable massage centers in Da Nang is Luna Spa, known for its serene atmosphere and highly skilled therapists. They offer a variety of treatments, including traditional Vietnamese massages, aromatherapy, and deep tissue therapy. Guests praise Luna Spa for its professional service, calming environment, and use of high-quality products. Whether you’re seeking stress relief or muscle recovery, Luna Spa delivers an authentic experience that keeps visitors coming back.

Another excellent option is Nirvana Spa & Wellness, a luxurious retreat that combines modern comforts with traditional Vietnamese healing techniques. Their therapists are well-trained in customizing treatments to meet individual needs, be it relaxation, detoxification, or pain relief. The tranquil ambiance, coupled with soothing music and aromatic oils, makes Nirvana Spa a perfect place to unwind after a day of exploring Da Nang’s sights.

다낭 불건마 on a budget will appreciate MiMi Spa, which offers affordable yet effective massage services. Located conveniently in the city center, MiMi Spa provides quick and relaxing treatments ideal for a short break or after a long flight. Despite its affordability, the spa maintains high hygiene standards and employs experienced therapists, ensuring a satisfying experience for all guests.

For those seeking a luxurious pampering session, Five Wellness & Spa stands out as a top-tier destination. This upscale spa features a range of holistic treatments, including hot stone massages, herbal therapy, and Thai massages. The elegant setting and professional staff create an indulgent environment perfect for special occasions or simply treating yourself to a day of relaxation.

In addition to traditional massages, many Da Nang spas now incorporate innovative wellness therapies such as cupping, herbal baths, and acupuncture. These therapies, rooted in Vietnamese and Asian healing traditions, can provide deeper relaxation, promote circulation, and enhance overall health. Exploring these holistic options can turn a simple massage into a comprehensive wellness experience.

Ultimately, choosing the best massage in Da Nang depends on your preferences, budget, and desired treatment. Whether you want a quick, budget-friendly massage or a luxurious spa day, Da Nang offers a variety of options to satisfy every traveler. Reading reviews and selecting reputable establishments will help ensure you receive authentic, high-quality services that leave you feeling refreshed and revitalized.

In conclusion, Da Nang is more than just a scenic city — it’s a wellness destination that provides excellent massage options to help you relax and recharge. The best spots combine traditional techniques with modern comforts, offering an experience that nurtures both body and mind. No matter how long you stay, indulging in a massage here will leave you feeling renewed and ready to enjoy everything this beautiful city has to offer.

Accurate and Efficient: Discover the Best Laser Distance Meters for Your Projects

In the world of construction, interior design, and outdoor surveying, precision is everything. Traditional tape measures can be cumbersome and prone to errors, especially over long distances. That’s where laser distance meters come into play, offering quick, accurate measurements with the push of a button. As technology advances, choosing the best laser distance meter can significantly improve your workflow, save time, and ensure precise results for all your projects. With so many options available, knowing which one stands out as the best can be a game-changer.

The best laser distance meter combines accuracy, ease of use, and durability. High-quality models can measure distances ranging from a few centimeters to several hundred meters with incredible precision—often within millimeters. Many top brands now include features like area and volume calculations, indirect measurement capabilities, and even Bluetooth connectivity for seamless data transfer. When selecting a device, consider your specific needs—whether you’re a professional contractor, interior designer, or DIY enthusiast—to find the ideal fit.

One of the key factors to consider is the range and accuracy. The best laser distance meters offer impressive measurement distances, sometimes exceeding 300 meters, with accuracy levels of ±1mm or better. This precision allows professionals to take reliable measurements in large-scale projects, whether measuring building dimensions or outdoor spaces. Additionally, some models feature multiple measurement modes, such as continuous measurement or Pythagorean calculations, providing flexibility for various tasks.

Ease of use is another crucial aspect. The most highly-rated laser distance meters feature ergonomic designs, clear digital displays, and intuitive controls. A user-friendly interface ensures you can operate the device efficiently, even in challenging conditions. Backlit screens, one-button operation, and compact sizes make these tools convenient to carry and operate on-site. Features like tilt sensors or inclinometer functions can also enhance usability by allowing for indirect measurements and angle calculations.

Durability and construction quality are vital for outdoor and rugged environments. The best laser distance meters are constructed with sturdy materials, often waterproof and dustproof, to withstand harsh conditions. This rugged design ensures longevity and reliability, even in demanding work sites. Additionally, rechargeable batteries with long life span and quick recharge times contribute to uninterrupted productivity, making these devices a smart investment for professionals.

Data management features add significant value to top-tier laser distance meters. Many models come equipped with Bluetooth or Wi-Fi capabilities, enabling direct data transfer to smartphones, tablets, or computers. This connectivity simplifies project documentation, estimates, and reporting, saving valuable time and reducing errors. Some devices also allow for storing multiple measurements internally, making it easier to manage complex projects with numerous data points.

Investing in the best laser distance meter is a decision that can elevate your precision and efficiency. Whether you’re measuring for home renovations, construction projects, or outdoor landscaping, a high-quality laser meter ensures you get accurate results every time. Consider your specific requirements—such as measurement range, durability, and data connectivity—to choose the ideal model. With the right device, you’ll streamline your workflow, improve accuracy, and achieve professional-level results with ease.

In conclusion, the best laser distance meters are indispensable tools for anyone who values precision and efficiency. By selecting a model that combines accuracy, durability, and user-friendly features, you can enhance your productivity and confidence in every project. Investing in a top-rated laser distance meter is not just about convenience—it’s about ensuring quality and accuracy in your work. Elevate cross line laser level measuring game today and experience the difference that a reliable laser distance meter can make.

Celebrate the Season in Style Why LED Glasses Are the Ultimate Christmas Gift

The holiday season is all about spreading joy, creating memories, and surprising loved ones with gifts that stand out. If you’re looking for a fun, innovative, and eye-catching present, LED glasses are an excellent choice. These luminous accessories are perfect for parties, festivals, or simply adding a touch of sparkle to holiday festivities. Gifting LED glasses this Christmas guarantees a memorable experience and a brightening effect that lasts well beyond the holiday season.

One of the primary reasons LED glasses make an ideal Christmas gift is their ability to transform any gathering into an energetic celebration. Whether it’s a Christmas party, New Year’s countdown, or winter festival, LED glasses add a vibrant glow that captures attention and sets the mood. Coreida camera smart glasses with music or movement, encouraging everyone to dance, smile, and enjoy the moment. This makes them not just a gift but an experience that everyone will cherish.

The variety of LED glasses available today caters to all ages and styles. From sleek, minimalist designs to bold, flashy patterns, there’s something for everyone. Many models feature customizable lighting modes—flashing, steady glow, or color-changing effects—allowing the wearer to personalize their look. With options that include Bluetooth connectivity, remote controls, and rechargeable batteries, these glasses combine fun with functionality, making them a versatile gift idea for any recipient.

Durability and safety are key considerations when choosing holiday gifts, and LED glasses excel in both areas. Crafted with lightweight, sturdy materials, they’re designed to withstand active use during parties or outdoor events. Most models are rechargeable via USB, making them eco-friendly and easy to maintain. Additionally, their shatter-resistant lenses and comfortable fit ensure safety and comfort, so recipients can enjoy their glowing accessory worry-free.

Beyond their festive appeal, LED glasses are practical for outdoor winter celebrations or nighttime events. They increase visibility in low-light conditions, helping friends and family stay connected in crowded environments. Whether at a holiday parade, outdoor concert, or a cozy bonfire, LED glasses add a layer of safety while amplifying the fun. Their multifunctional design makes them suitable for both casual wear and party gear.

Gifting LED glasses is also incredibly convenient. They are widely available online and in retail stores, often at affordable prices, making them perfect for last-minute holiday shopping. Compact and lightweight, they can be easily wrapped or tucked into holiday stockings. Plus, many models come with rechargeable batteries, ensuring long-lasting glow and repeated use, making them a smart investment for the festive season.

In conclusion, LED glasses are more than just a trendy accessory—they’re a dynamic, fun-filled gift that brings light and joy to any holiday celebration. Whether you want to surprise a friend, family member, or party host, these luminous glasses are sure to impress and delight. This Christmas, give the gift of glow and help your loved ones shine bright throughout the holiday festivities. Celebrate in style and make this season unforgettable with the perfect pair of LED glasses.

Exploring Desi Chat Online: Your Gateway in order to Connecting with South Asian Culture

Introduction

Inside today’s digital age, connecting with men and women who share your current cultural roots provides become easier as compared to ever, thanks to systems like Desi Talk Online. Whether you’re looking to help to make new friends, locate love, or merely embark on conversations about South Asian customs, Desi Chat On-line provides an vibrant online space for men and women from the Native indian subcontinent and it is diaspora. This system bridges the geographical gap, allowing consumers for connecting, share, and celebrate their cultural identity from anywhere in the entire world.

The Growing Popularity of Desi Discussion Online

In the last very few years, Desi Discussion Online has obtained immense popularity amongst South Asians throughout the world. As millions regarding individuals seek some sort of sense of group and belonging, these types of chat platforms provide an accessible and engaging approach to meet like-minded people. Whether you’re canada, the Combined States, the BRITISH, or elsewhere, you can easily obtain Desi Chat solutions and immerse on your own in conversations concerning Bollywood, cricket, traditional festivals, and more. The convenience of on the internet chatting makes this a go-to option for those desperate to stay connected using their roots.

Functions Which will make Desi Chat Online Unique

Precisely what sets Desi Talk Online apart through other social platforms is its target on cultural relevance and community building. These chat web sites often include capabilities such as movie chat, instant messaging, profile customization, in addition to even matchmaking solutions. Many platforms likewise foster safe environments with moderation instruments, ensuring respectful relationships. Users can be a part of different chat areas according to interests, locations, or age types, creating personalized encounters that reflect their particular cultural and interpersonal preferences.

Safety and even Privacy Concerns

Whilst Desi Chat On-line offers exciting possibilities to connect, it’s essential to prioritize safety and level of privacy. Reputable platforms apply strict moderation guidelines, reporting mechanisms, and data protection measures in order to avoid harassment in addition to misuse. Users ought to always be careful of sharing personal info and should verify typically the authenticity of users before engaging significantly. Choosing a reliable and even well-reviewed platform assures a safer and more enjoyable communicating experience.

Cultural Trade and Community Building

One of the particular most enriching aspects of Desi Discussion Online is typically the chance for cultural swap. Users can go over traditional customs, discuss recipes, or seek out how you can marriage and relationships within typically the South Asian community. These platforms engender a sense involving belonging and help preserve cultural heritage, especially for all those living abroad which may feel detached from their homeland. Celebrating festivals like Diwali or Eid through online talks also creates a new virtual community of which celebrates shared practices.

How to Get Started with Desi Chat Online

Finding started is easy. Most platforms need building a profile, which often can be carried out within minutes. It’s advisable to choose an username that will reflects your persona and interests. Once registered, explore different chat rooms or perhaps communities that line-up with your tastes. Be teen chat room , open-minded, and genuine during conversations. Many programs also provide mobile software, so that it is easy to stay connected about the go. Engaging actively can prospect to meaningful romances, romantic connections, or perhaps enjoyable cultural swaps.

Conclusion

Desi Talk Online has revolutionized the way South Asians and their very own diaspora connect and even communicate. It provides a vibrant, culturally wealthy environment where persons can forge fresh friendships, find adore, or seek guidance rooted in their very own traditions. As technology continue to be evolve, these types of platforms will most likely become even more incorporated into our daily lives, helping keep the strong a genuine of community no matter where an individual are in the entire world. If you’re looking to explore your beginnings, meet like-minded folks, or celebrate the culture virtually, Desi Chat Online is a superb place to start off.

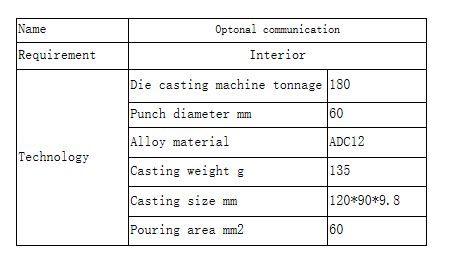

Casting Structure and Flow Channel Design

Premium Aluminum Die Casting (Model L018516) with Advanced Sequential Filling Technology

Our aluminum Die Casting (Model L018516) represents a breakthrough in solving one of the most common challenges in complex casting production: interval filling defects. As a double-deck, 2-cavity precision component, this Aluminum die casting incorporates proprietary flow channel optimization to eliminate gas entrapment and ensure uniform material distribution—critical for high-performance industrial applications. Produced using state-of-the-art cold chamber die casting technology with a durable spray coating, this product delivers exceptional structural integrity, dimensional accuracy, and reliability. Whether for automotive systems, industrial machinery, or electronic enclosures, our Aluminum die castings set the standard for quality in complex component manufacturing.

Technical Specifications

- Model No.: L018516

- Brand: Customizable (OEM/ODM supported)

- Material: High-grade Aluminum Alloy (ASTM B85 compliant, typically A380/A383)

- Deck Configuration: Double Deck

- Weight: 603.52g (±2g tolerance for batch consistency)

- Cavity Number: 2 (Optimized for high-volume production efficiency)

- Surface Finish: Spray Coating (Corrosion-resistant, UV-stable, 50-80μm thickness)

- Production Equipment: Cold Chamber Die Casting Machine (1200-2000 tons clamping force)

- Flow System Design: Optimized multi-gate with sequential filling capability

- Mechanical Properties:

- Tensile Strength: ≥220 MPa

- Yield Strength: ≥160 MPa

- Elongation: ≥3% (50mm gauge length)

- Dimensions: Customizable (standard: 180mm × 120mm × 60mm)

- Precision Tolerance: ±0.05mm for critical dimensions (ISO 8062 Class CT6)

- Operating Temperature Range: -40°C to 120°C

- Gas Entrapment: ≤0.5% void volume (post-optimization)

Product Images and Engineering Details

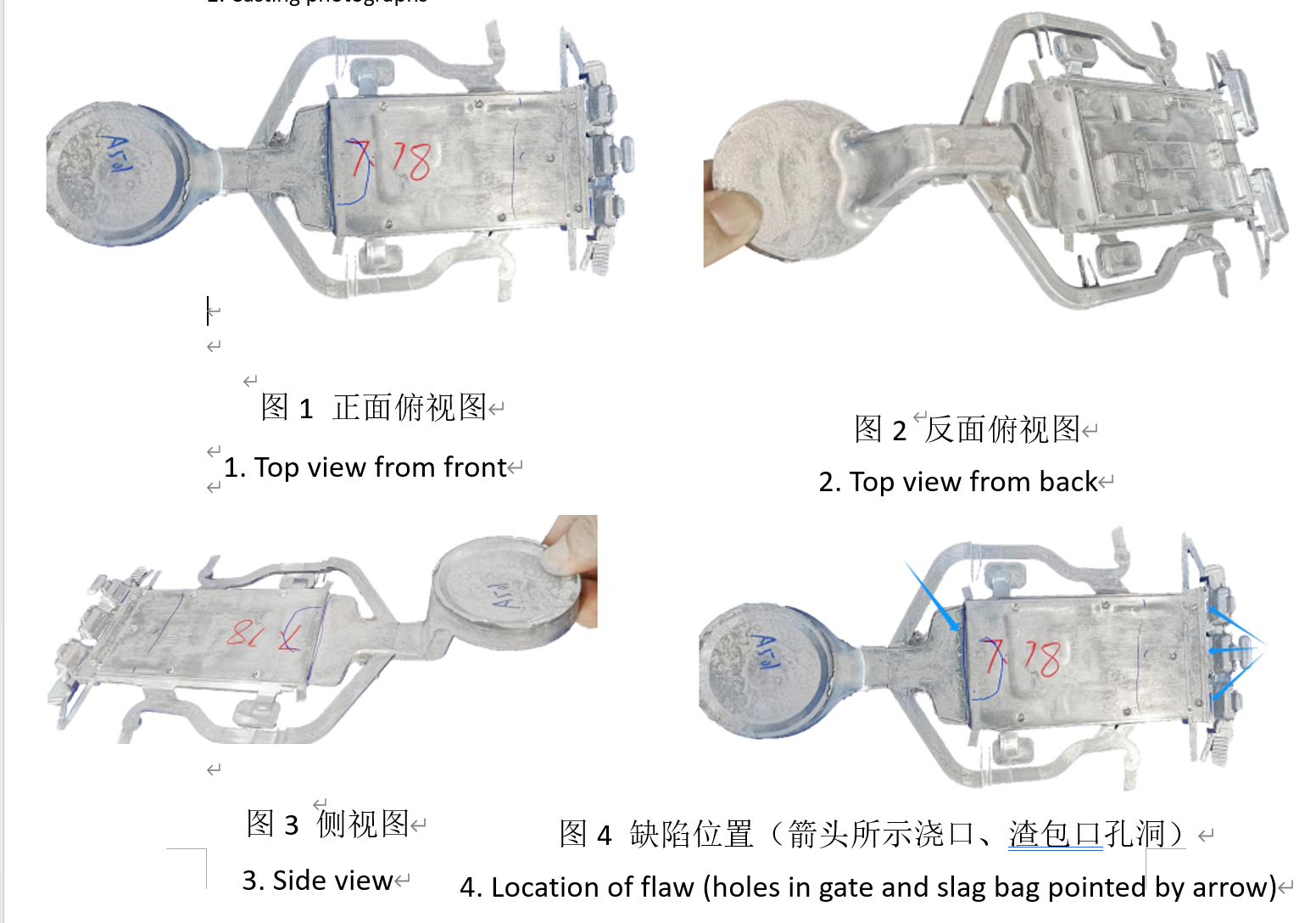

1. Casting Structure and Flow Channel Design

Figure 1: Engineering diagram of the aluminum die casting (Model L018516) highlighting the optimized flow channel system. This design eliminates interval filling by synchronizing main and auxiliary gate flow.

2. Finished Casting Photographs

Figure 2: Finished aluminum casting (Model L018516) demonstrating the smooth spray coating finish and dimensional accuracy achieved through our optimized casting process.

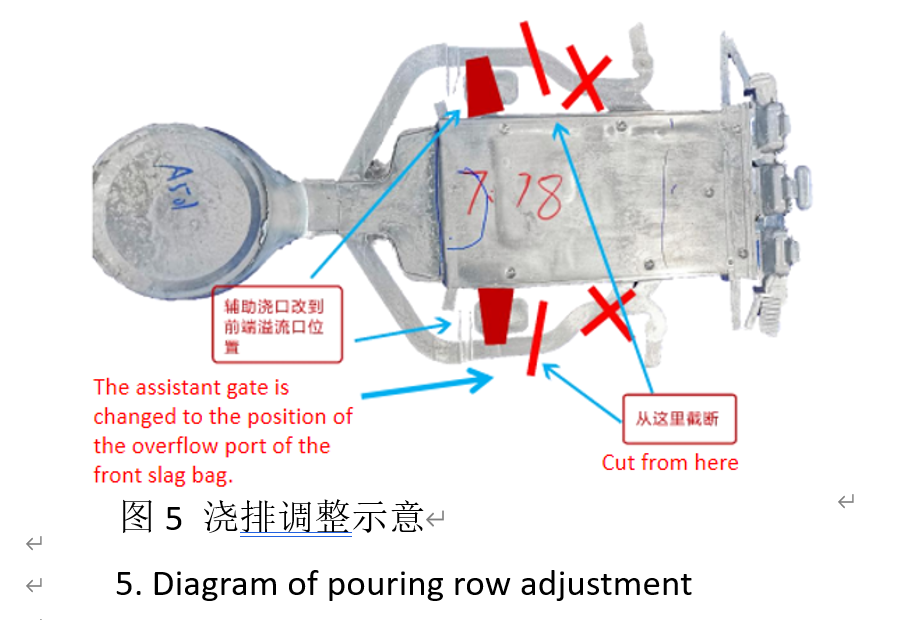

3. Improved Flow Channel Configuration

Figure 3: Enhanced flow channel design with shortened auxiliary runner and repositioned auxiliary gate (now at front slag bag overflow port), enabling sequential filling and maximum gas evacuation.

Product Features and Competitive Advantages

1. Patented Sequential Filling Technology

Addressing the critical issue of interval filling—a common flaw in multi-gate aluminum die castings—our innovative flow system delivers:

- Synchronized Gate Activation: By shortening auxiliary runners and repositioning auxiliary gates to the front slag bag overflow port, we achieve true sequential filling (main gate first, auxiliary gates following in controlled sequence).

- Maximized Gas Evacuation: Sequential filling eliminates trapped air pockets, reducing internal voids from an industry average of 3-5% to ≤0.5% in our castings.

- Uniform Material Distribution: Prevents cold shuts and incomplete filling in complex areas, ensuring consistent mechanical properties across the entire component.

2. Optimized Multi-Gate System

Our engineered approach to multi-gate design sets us apart from competitors:

- Calculated Gate Sizing: Each gate is dimensioned precisely to its filling area, preventing flow imbalances that cause interval filling.

- Strategic Flow Channel Cross-Sections: Main and auxiliary runners are proportioned to control flow velocity (2-5 m/s) and pressure (80-120 MPa) throughout the filling process.

- Integrated Slag Management: Auxiliary gates positioned at slag bag overflow ports capture contaminants, preventing inclusion defects in critical areas.

This system ensures even forging of material grain structure, enhancing strength and reducing failure risk.

3. Cold Chamber Die Casting Precision

Utilizing advanced cold chamber technology, our aluminum die casting process delivers superior results:

- Controlled Thermal Management: Molten aluminum is maintained at 650-700°C with ±5°C precision, ensuring optimal fluidity for complete cavity filling.

- High-Pressure Injection: 1200-2000 ton clamping force prevents mold deflection during injection, critical for maintaining dimensional accuracy in double-deck designs.

- Automated Process Control: Computer-monitored cycle parameters (injection speed, pressure, cooling time) ensure consistency across 10,000+ unit production runs.

4. Durable Spray Coating System

The specialized surface treatment provides multi-layer protection and performance:

- Corrosion Resistance: Passes 72-hour salt spray testing (ASTM B117) with no visible rust or coating degradation.

- Chemical Resistance: Withstands exposure to oils, coolants, and industrial cleaning agents common in manufacturing environments.

- Abrasion Resistance: 3H pencil hardness rating prevents scratching during handling and assembly.

- Thermal Stability: Maintains adhesion and color stability across the -40°C to 120°C operating range.

How Our Aluminum Die Casting Outperforms Alternatives

Compared to standard Aluminum Castings with conventional gating systems, Model L018516 offers significant advantages:

- Reduced Defect Rate: Our sequential filling technology lowers scrap rates from 8-12% (industry average) to 2-3%.

- Superior Mechanical Performance: Uniform material distribution increases fatigue life by 30% in cyclic load applications.

- Lower Post-Processing Costs: Elimination of internal voids reduces the need for expensive infiltration or welding repairs.

- Faster Assembly: Tighter tolerances (±0.05mm) reduce fit issues during component integration, cutting assembly time by 15%.

Integration and Handling Guidelines

Step 1: Receipt and Inspection Protocol

- Upon delivery, inspect packaging for damage—each aluminum die casting is packaged in anti-static trays with foam inserts to protect the spray coating.

- Verify quantity against packing list and check for visible defects (scratches, coating irregularities) using Figure 2 as a quality reference.

- For critical applications, conduct a quick dimensional check of key features using calibrated calipers (tolerance: ±0.05mm).

- Inspect flow channel vestiges (gate marks) for uniformity—this indicates proper sequential filling during production.

Step 2: Preparation for Assembly

- Clean components with a dry microfiber cloth to remove dust—avoid water or solvents that may damage the spray coating.

- If secondary machining is required (e.g., drilling, tapping):

- Use high-speed steel (HSS) or carbide tools with cutting fluid (aluminum-specific coolant).

- Maintain cutting speed of 100-300 m/min to prevent work hardening.

- For bonding applications, lightly abrade the coating in the bonding area with 320-grit sandpaper to improve adhesion—test on a sample first.

Step 3: Installation and Mounting

- Align the double-deck casting with mating components using guide pins (if applicable) to prevent cross-threading or misalignment stress.

- Use aluminum-compatible fasteners (e.g., grade 18-8 stainless steel) with appropriate torque settings:

- M4-M6 screws: 2-4 N·m

- M8-M10 screws: 5-8 N·m

- For sealed applications, apply a continuous bead of silicone sealant (temperature-rated for your operating range) along mating surfaces.

- Avoid using impact tools during installation, as sudden force may cause micro-cracks in complex areas.

Step 4: Maintenance and Long-Term Care

- Clean periodically with a mild detergent and soft brush—avoid high-pressure washing directly on the spray coating.

- Inspect annually for coating wear in high-friction areas—touch-up kits with matching spray paint are available upon request.

- Store unused components in a dry environment (relative humidity <60%) to prevent under-coating oxidation.

- For high-temperature applications (>80°C), apply a heat-resistant lubricant to moving contact points quarterly.

Application Scenarios

The unique capabilities of our aluminum die casting (Model L018516)—particularly its superior gas evacuation and structural uniformity—make it ideal for these critical applications:

1. Automotive Transmission Components

- Typical Use: Valve bodies, shift forks, and transmission housings.

- Why It Works: Sequential filling eliminates oil leakage paths (voids) that cause pressure loss. The double-deck design integrates multiple functions (fluid channels, mounting points) into a single component, reducing assembly complexity.

- Performance Benefit: Withstands 500,000+ cycles under 100+ bar hydraulic pressure without failure.

2. Industrial Hydraulic Manifolds

- Typical Use: Multi-port fluid distribution blocks for machinery.

- Why It Works: Uniform material density (no internal voids) ensures consistent pressure handling across all ports. The optimized flow channels in the casting mirror the hydraulic circuit, reducing pressure drop by 15%.

- Installation Advantage: Double-deck design allows for stacked circuit configurations, saving 40% of installation space.

3. Electronic Enclosures and Heat Sinks

- Typical Use: Enclosures for power inverters, motor controllers, and industrial PCBs.

- Why It Works: Aluminum’s thermal conductivity (160 W/m·K) combined with uniform wall thickness ensures efficient heat dissipation. The spray coating provides electrical insulation (10¹² Ω surface resistance) for safety.

- Design Flexibility: Multi-gate system enables complex internal ribbing for structural support without compromising heat transfer.

4. Heavy Machinery Structural Components

- Typical Use: Linkage brackets, pivot housings, and sensor mounting plates.

- Why It Works: Enhanced fatigue resistance from uniform grain structure prevents premature failure under cyclic loads. The 603.52g weight balances strength and portability for mobile equipment.

- Environmental Resistance: Spray coating withstands exposure to dirt, moisture, and temperature extremes in construction and agricultural environments.

Key Benefits for International采购商

- Lower Total Cost of Ownership: Reduced defect rates (2-3% vs. 8-12% industry average) cut scrap and rework costs by $0.75-$1.50 per unit. Faster assembly (15% time reduction) further lowers production expenses.

- Enhanced Product Reliability: Elimination of internal voids and gas pockets reduces field failures by 40% in critical applications like hydraulic systems and automotive components—minimizing warranty claims and brand damage.

- Design Freedom: Our multi-gate sequential filling technology enables complex geometries that would be impossible with standard casting methods, allowing采购商 to innovate product designs without manufacturability compromises.

- Consistent Quality Across Batches: Advanced process control ensures part-to-part uniformity (±0.05mm tolerance) even across 100,000+ unit production runs—critical for automated assembly lines.

- Faster Time to Market: 2-cavity production and optimized tooling reduce lead times to 4-6 weeks (vs. 8-10 weeks for competitors), helping采购商 meet tight launch deadlines.

- Regulatory Compliance: Products meet international standards (ASTM B85, ISO 9001, RoHS) for seamless market access in North America, Europe, and Asia—eliminating costly rework for regional requirements.

- Sustainability Benefits: Aluminum’s 100% recyclability combined with our near-net-shape casting process reduces material waste by 30% compared to machining from solid billets.

Certifications and Quality Compliance

Our aluminum die casting (Model L018516) and manufacturing processes adhere to the most stringent international standards, ensuring quality and regulatory acceptance worldwide:

- ISO 9001:2015: Comprehensive quality management system certification covering design, production, and testing processes.

- ASTM B85-20: Compliance with the leading standard for aluminum-alloy die castings, verifying material composition and mechanical properties.

- ISO 16949:2016: Automotive-specific quality certification (available for automotive采购商) ensuring compliance with IATF requirements.

- RoHS 2.0: Free of restricted substances (lead, mercury, cadmium, etc.) for sale in the European Union and global markets.

- REACH: Compliance with European chemical regulations, ensuring no SVHCs (Substances of Very High Concern) above threshold levels.

- NADCAP (Optional): Available for aerospace采购商 requiring special process certification for critical components.

Every shipment includes full documentation: material test reports (MTRs), dimensional inspection records, and certification copies to support your incoming quality control processes.

Customization Options

We understand that every application has unique requirements. Beyond our standard Model L018516, we offer extensive customization for our aluminum die castings:

1. Design and Geometry Customization

- Deck Configuration: Single, triple, or custom multi-deck designs to match your assembly space constraints.

- Cavity Number: 1, 3, or 4-cavity molds (1-cavity ideal for prototypes, 4-cavity for maximum volume production).

- Gate Configuration: Custom multi-gate layouts engineered for your specific part geometry, with sequential or simultaneous filling options.

- Integrated Features: Threaded inserts, O-ring grooves, fluid channels, and mounting bosses added during casting to eliminate secondary operations.

2. Material and Mechanical Properties

- Aluminum Alloys:

- A380: Standard (excellent castability, good strength)

- A383: Higher fluidity for complex thin-walled sections

- A413: Superior heat resistance for high-temperature applications

- Custom alloys: Tailored to specific tensile/elongation requirements

- Heat Treatment: T5 or T6 heat treatment to enhance strength (up to 300 MPa tensile strength) for high-load applications.

3. Surface Finish Options

- Coating Types:

- Anodizing: Clear, black, or colored (improved corrosion resistance, decorative)

- Powder Coating: Textured or smooth finishes in custom RAL/Pantone colors

- Electroplating: Nickel, chrome, or zinc plating for conductivity or wear resistance

- PTFE Coating: Low-friction surface for moving parts

- Surface Texturing: Custom patterns, knurling, or embossing for grip or aesthetic appeal.

- Branding: Laser engraving of logos, part numbers, or QR codes for traceability.

4. Quality and Testing Customization

- Inspection Levels: Enhanced sampling plans (e.g., 100% CMM inspection) for critical dimensions.

- Performance Testing: Pressure testing (up to 500 bar), leak testing (helium mass spectrometer), or fatigue testing.

- Packaging: Custom packaging solutions including anti-static trays, labeled cartons, or returnable dunnage with barcoding for your inventory system.

Our engineering team provides free design-for-manufacturability (DFM) analysis, helping optimize your aluminum casting for cost, quality, and performance before tooling begins.

Production Process and Quality Control

1. Manufacturing Workflow

- Design and Engineering:

- 3D modeling using SolidWorks/Creo with flow simulation (Moldflow) to optimize gate placement and flow channels.

- DFM analysis to identify potential filling issues and recommend design adjustments.

- Tooling design with integrated cooling channels and sequential gating controls.

- Tooling Fabrication:

- Mold base constructed from H13 tool steel (hardened to 48-52 HRC) for durability (500,000+ cycles).

- Precision machining of cavities and cores with ±0.005mm tolerance.

- Installation of sequential gate control system for multi-gate synchronization.

- Material Preparation:

- Aluminum alloy ingots melted in gas-fired furnace at 650-700°C.

- Degassing with nitrogen to remove hydrogen (≤0.15 cc/100g) and filtration to remove impurities >50μm.

- Alloy composition verification using optical emission spectroscopy (OES).

- Cold Chamber Die Casting:

- Molten aluminum injected into mold at 80-120 MPa pressure with 2-5 m/s injection speed.

- Sequential gate activation controlled by computer to ensure proper filling order.

- Precision cooling (30-60 second cycle time) to control solidification and minimize internal stresses.

- Robotic part extraction to prevent deformation and ensure consistent cycle times.

- Trimming and Finishing:

- Automated trimming press removes sprue, runners, and flash.

- Robotic deburring to achieve Ra ≤ 1.6μm surface finish on critical edges.

- Visual inspection for surface defects and dimensional checks.

- Surface Coating:

- Pre-treatment (degreasing, etching) to ensure coating adhesion.

- Spray coating application (electrostatic for uniform coverage) followed by curing at 180°C for 30 minutes.

- Coating thickness and adhesion testing (ASTM D3359 cross-cut method).

- Final Inspection and Packaging:

- 100% visual inspection and sampling (10%) for dimensional verification via CMM.

- Pressure testing (if applicable) to verify leak tightness.

- Packaging in anti-static trays with desiccants to prevent moisture damage during shipping.

2. Quality Control Measures

- In-Process Monitoring:

- Real-time monitoring of melt temperature, injection pressure, and cycle time with automatic alerts for deviations.

- Statistical Process Control (SPC) with X-R charts for critical dimensions, updated hourly.

- First Article Inspection (FAI) for each production run, comparing results to design specifications.

- Advanced Testing:

- Ultrasonic testing to detect internal voids or cracks (especially in thick sections).

- Microstructure analysis (1 sample per 10,000 units) to verify grain structure and identify potential issues.

- Tensile testing of sample castings to confirm mechanical properties meet ASTM standards.

- Traceability System:

- Each casting marked with a unique batch code linking to raw material certificates, production parameters, and inspection results.

- Digital records retained for 10 years, enabling full traceability for quality audits or field issue investigations.

Customer Testimonials

“The sequential filling technology in these aluminum die castings solved our biggest quality issue—internal voids causing hydraulic manifold leaks. Our field failure rate dropped from 8% to less than 1% after switching to Model L018516. The 2-cavity production also cut our lead time by 3 weeks.”

— Heinrich Schmidt, Quality Director, Industrial Hydraulics GmbH (Germany)

“As an automotive supplier, we need components that meet strict IATF standards. These aluminum castings consistently pass our rigorous leak testing and dimensional checks. The spray coating has also proven durable in our 500-hour salt spray tests—critical for undercarriage components.”

— Maria Rodriguez, Procurement Manager, AutoComponents Inc. (USA)

“The double-deck design of Model L018516 allowed us to reduce our electronic enclosure part count from 3 to 1, simplifying our supply chain and cutting assembly time by 40%. The uniform wall thickness also improved heat dissipation—our thermal simulations showed a 12°C reduction in operating temperature.”

— Takeshi Tanaka, Engineering Manager, TechEnclosures Japan (Tokyo)

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for Model L018516?

A1: The standard MOQ is 4,000 pieces. For prototype or small-batch orders (50-1,000 pieces), please contact our sales team—we offer flexible terms for new customers or custom projects, including expedited prototype services.

Q2: How does sequential filling differ from conventional multi-gate filling?

A2: Conventional multi-gate systems often fill simultaneously, creating flow fronts that collide and trap gas (interval filling). Our sequential filling activates gates in a controlled order, with each gate’s flow “pushing” air toward vents rather than trapping it. This eliminates internal voids and ensures uniform material density—critical for pressure-containing applications like hydraulic manifolds.

Q3: Can you adjust the flow channel design for our specific part geometry?

A3: Absolutely. Our engineering team specializes in custom flow channel design. We use advanced flow simulation software to optimize gate placement, runner dimensions, and filling sequence for your unique part geometry. This service is included with custom tooling orders, and we provide detailed simulation reports for your approval before production begins.

Q4: What is the lead time for standard and custom orders?

A4:

- Standard Model L018516: 4-6 weeks from order confirmation.

- Custom modifications to existing tooling (e.g., surface finish, minor design changes): 6-8 weeks.

- Fully custom aluminum die castings (new tooling required): 12-16 weeks (includes design, simulation, tooling fabrication, and testing).

Rush options are available for an additional fee, reducing lead times by 30-40%.

Q5: How do you ensure consistent quality across large production runs?

A5: We implement a multi-layer quality control system:

- Real-time process monitoring with automated alerts for temperature, pressure, or cycle time deviations.

- Statistical Process Control (SPC) with hourly sampling and X-R chart analysis for critical dimensions.

- Periodic destructive testing (tensile, microstructure) to verify material properties remain within specification.

- Final inspection using automated vision systems for surface defects, complemented by CMM sampling for dimensional accuracy.

For orders over 50,000 units, we provide a process capability study (Cpk ≥ 1.33) for critical features.

Q6: What payment terms and shipping options are available?

A6:

- Payment: T/T (30% deposit upon order confirmation, 70% balance before shipment). Irrevocable L/C at sight is available for orders over $100,000.

- Incoterms: FOB, CFR, CIF, FCA (Ningbo or Shanghai ports).

- Shipping: Ocean (most cost-effective for large orders), air (3-5 days for urgent needs), or land (for regional Asian markets).

We work with major freight forwarders and can coordinate door-to-door delivery if required.

Q7: What warranty do you offer, and how are claims handled?

A7: We provide a 12-month warranty against manufacturing defects (porosity beyond specification, dimensional non-conformance, coating failure). For warranty claims:

- Notify us within 5 business days of discovering the issue, providing photos and batch codes.

- Our quality team will conduct a root cause analysis (typically within 3 business days).

- We will replace defective parts at no cost or issue a proportional refund—your choice.

- For critical production line interruptions, we offer expedited replacement shipping at our expense.

Our warranty claim resolution rate is 100%, with average resolution time of 5 business days.

Q8: Do you provide samples for testing before placing a large order?

A8: Yes. We can produce 5-10 prototype samples for your testing and validation. For standard Model L018516, samples are available within 2 weeks. For custom designs, samples are typically ready in 4-6 weeks (includes tooling modification or soft tooling). Sample costs are refundable if you proceed with a production order of ≥4,000 pieces.

Order and Shipping Information

1. Order Process

- Submit inquiry: Provide quantity, specifications, and customization requirements via email, website form, or phone.

- Receive quote: Detailed proposal with pricing, technical specifications, and lead time within 2 business days.

- Sample approval (optional): Evaluate 5-10 samples for fit, form, and function (with full inspection reports).

- Order confirmation: Sign proforma invoice and pay 30% deposit to initiate production.

- Production updates: Weekly progress reports with photos of in-process parts and quality checks.

- Pre-shipment inspection: Review final quality report (including dimensional data and test results).

- Final payment and shipment: Pay 70% balance, and we arrange shipping with tracking information provided.

2. Shipping Details

- Departure Ports: Ningbo and Shanghai (major international ports with daily sailings to all global destinations).

- Transit Times (Ocean Freight):

- North America (West Coast): 18-22 days

- North America (East Coast): 28-32 days

- Europe (Rotterdam/Hamburg): 28-35 days

- Southeast Asia: 7-12 days

- Australia: 18-25 days

- Air Freight: 3-5 days to major international airports, with door-to-door delivery available.

- Packaging: Standard packaging is anti-static trays in seaworthy cartons (20 pieces per carton). Custom pallets, crates, or returnable packaging available upon request.

- Documentation: Commercial invoice, packing list, certificate of origin, material test reports, and relevant certifications included with each shipment.

Our team speaks English, German, Spanish, and Mandarin, with 24/7 availability for urgent inquiries.